The Durability Advantages of Excavator Buckets Made with Hardox® Steel

- oyildiz0

- Aug 6

- 2 min read

When it comes to excavator and loader buckets, durability is everything. Equipment operating in harsh environments—such as mining, construction, or demolition—requires components that can withstand extreme wear and tear. That’s where Hardox® wear plate makes a significant difference.

What is Hardox Steel?

Hardox is a brand of abrasion-resistant (AR) steel developed by SSAB, a Swedish steel manufacturer. Known for its exceptional hardness, strength, and toughness, Hardox is engineered to perform in the most demanding working conditions.

Unlike standard steels, Hardox provides:

A significantly longer service life

High resistance to wear, impact, and deformation

Lightweight yet high-strength construction

These properties make it ideal for excavator buckets used in industries such as mining, quarrying, recycling, and heavy construction.

How Does Hardox Improve Excavator Bucket Performance?

Excavator buckets made with Hardox wear plate offer numerous performance benefits:

1. Extended Wear Life

Hardox can last two to three times longer than conventional steel. This results in fewer repairs, reduced downtime, and lower maintenance costs.

2. Increased Load Capacity

Thanks to its excellent strength-to-weight ratio, Hardox enables the construction of thinner yet tougher bucket walls—allowing for greater payloads without sacrificing durability.

3. Reduced Bucket Weight

Lighter buckets improve fuel efficiency and reduce stress on the machine, which is especially valuable during long operating hours.

4. Enhanced Resistance to Cracking and Deformation

Hardox maintains structural integrity under heavy impact, minimizing the risk of cracks and permanent deformation in extreme working conditions.

Applications That Benefit Most from Excavator Buckets Made with Hardox Steel

Hardox-reinforced excavator buckets are particularly well-suited for high-abrasion, high-impact applications, including:

Mining operations – handling abrasive rock and ore

Demolition work – where continuous impact and wear are expected

Quarrying – working with sharp and heavy materials

Recycling and scrap handling – unpredictable and demanding loads

Whether it's digging, loading, or hauling, buckets built with Hardox provide the durability and reliability your operations demand.

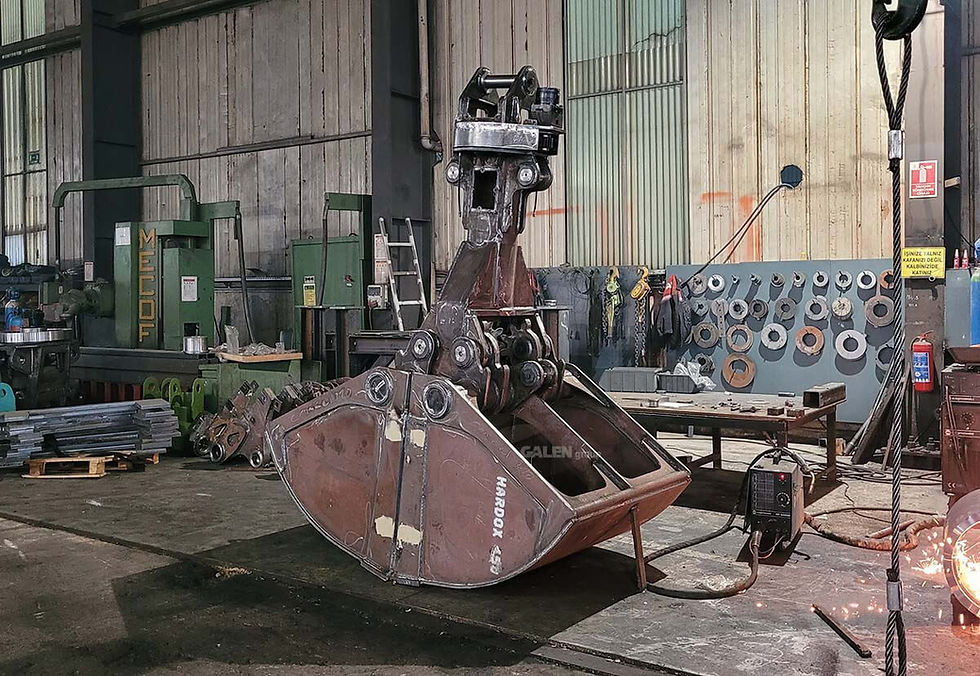

Why Choose Galen Buckets Made with Hardox?

At Galen Group, we use genuine Hardox wear plate in the manufacturing of our heavy-duty excavator buckets. By incorporating Hardox into our designs, we ensure that our products offer:

Outstanding resistance to wear and impact

Extended service life under the harshest conditions

A superior strength-to-weight ratio for enhanced machine performance

Our commitment to top-quality materials like Hardox allows us to deliver attachments that are durable, efficient, and highly dependable across demanding sectors such as mining, construction, and demolition.

Conclusion: Strength That Pays Off

Choosing excavator buckets made with Hardox steel is not just about durability—it’s an investment in long-term efficiency, reduced maintenance, and increased productivity. At Galen Buckets, we help you find the optimal wear solution for your application, delivering performance and value in every job.

Looking for a custom Hardox solution?

Contact Galen Group to speak with our engineering team about your project.